ADDED VALUE FOR YOUR BUSINESS

- Quality control backup of the product during all the process stages.

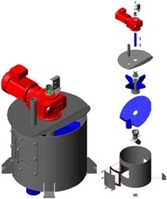

- Systems that allow the obtaining of representative samples of dry or wet ore, with a large range of particles sizes distribution.

- Fully automated systems, easy to operate and low maintenance cost.

- 100% domestic design and manufacture.

GENERAL FEATURES

More than 600 sampling units for slurry, dry ore solutions and wet concentrate operating individually or as a component of a more complex systems, make TecProMin S.A. into one of the world wide expert in this kind of equipment.

Sampling towers with 2-3 or 4 sampling stages and with 1 or 2 size reductions stages are some of the examples of the sampling solutions installed by our company, these are custom made and designed for every particular client and installations.

Our systems are manufactured following strictly the most rigorous sampling standards and rules used in mining publications, such as:

- “Pierre Gy’s Sampling Theorys and Sampling Practice” 2nd edition. Author: Prof. Francis F. Pitard, International Sampling Consultant.

- “Japanese Sampling StandardsJIS 8100”

- “Codelco Chile. Norma CNAM 007”

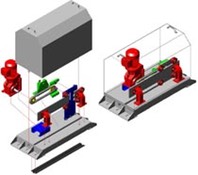

SAMPLING EQUIPMENT

- Sampler collector driven at a constant speed allows a representative sample.

- Cutter moves across line.

- Cutter opening can be adjusted or fixed.

- Fast unloading system to avoid flow overload.

- Spare parts easy maintenance.