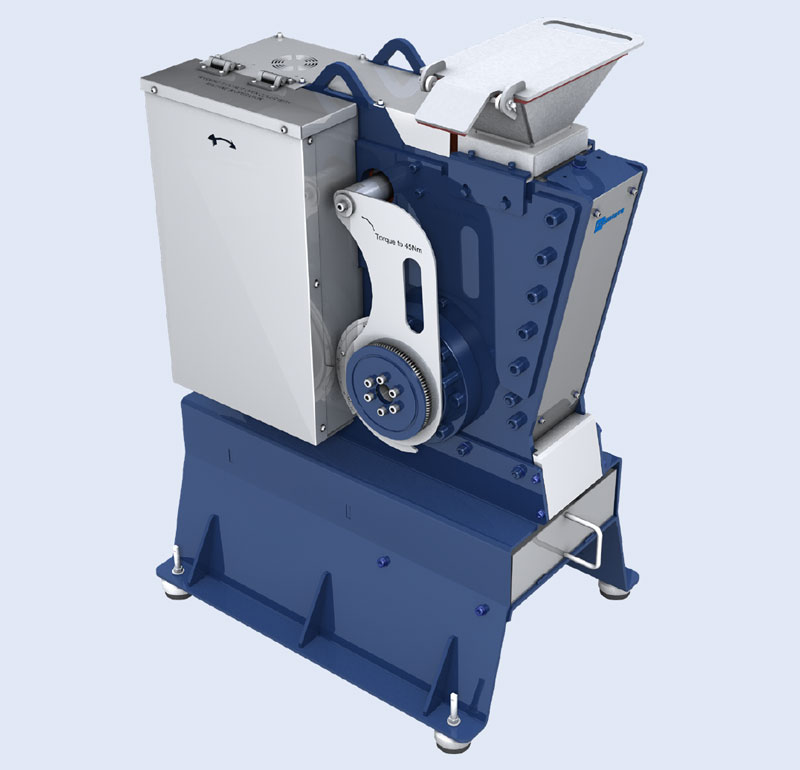

Built compact but strong, the Essa® JC1250 Jaw Crusher is a scaled down, more affordable version of the proven Essa® JC2501 for high productivity crushing.

Benefits

- Compact in size, affordable and reliable, but capable of impressive speed.

- 80 mm feed size handles a wide range of applications.

- 40:1 reduction ratio.

- Fast throughput for its size of up to 140 kg/hr to produce 85% passing 2 mm.

- Jaw plate opening size is extremely easy to adjust, with a reliable lock-in mechanism, for excellent control of product sizing.

- Low maintenance, meaning great savings with minimal ongoing costs.

- Easily accessible grease points for simple greasing.

- Meets industry standards and OH&S requirements.

- Built strong with rigid parts for increased availability.

Compact size and high workload

New to the market, the JC1250 Jaw Crusher has evolved from an intensive two and a half year research and development program. Modeled off the tried, tested and larger Essa® JC2501, the JC1250 packs power and value for high workload crushing. With a heavy duty 7.5 kW electric motor, the JC1250 equals that of the JC2501, but with half the crushing chamber width,

providing extra torque and power. It has an 80 mm feed size to handle relatively large material and is fast for a small crusher, maintaining a high throughput like its bigger brother the JC2501–

throughput of 140 kg per hour has been achieved, whilst producing 85% passing 2mm.

The JC1250 Jaw Crusher is designed to be used for crushing ores, minerals, metallurgical samples, ceramics and similar particulate. It is well suited to high volume mineral laboratories that regularly prepare rock and drill chip samples, or to any remote laboratory where minimal maintenance is an advantage.

User-friendly and dependable

Designed and built with the same reliable features as the long-term tested and proven JC2501, the Essa® JC1250 offers even better gap adjustment functionality. The crusher incorporates a

unique locking plate mechanism to simplify the adjustment and retention of the bottom jaw gap.

Adjusting the gap setting is now a quick and accurate process making it significantly easier to control product sizing, ensuring high quality sample preparation protocol is maintained. A safety feed hopper can be supplied as an option, which reduces the likelihood of material ejecting from the top, thereby reducing the chance of injury. It also prevents the operator from being able to place their hands in the crushing chamber while the crusher is operating.

Presenting great value

The bullet proof Essa® JC1250 combines the vital attributes of speed and reliability, making it one of the most affordable small crushers on the market. Despite its compact design, it can

handle a high workload – up to 5 kg comfortably – and has extraordinarily high productivity. The JC1250 is also built strong for increased availability and longevity. It comes standard with

anti-vibration mounts and a heavy duty fabricated steel base and side plate frame. This rigid design means minimal breakdowns. That, along with minimal ongoing costs, results in a low cost of ownership and presents extremely good value.

Ideally suited to rapidly fine-crush rock and drill chip samples

Ideally suited to rapidly fine-crush rock and drill chip samples

- Five easily accessible lubrication points that require greasing every 150 hours of operation.

- Heavy duty components and precise fabrication techniques for structural rigidity and alignment.

- Single dust extraction spigot allows for easy connection to the laboratory ducting system and minimizes operator exposure to dust.

- Reversible and interchangeable jaw plates.

- The gap adjustment has been ergonomically improved by means of an ingenious, yet simple, locking plate mechanism.

- No need to bolt the crusher to a concrete floor as it simply sits on four anti-vibration mounts.